Reverse Engineering & 3D Scanning

Aerospace-grade capabilities to 3D scan and reverse engineer automotive and motorsports applications

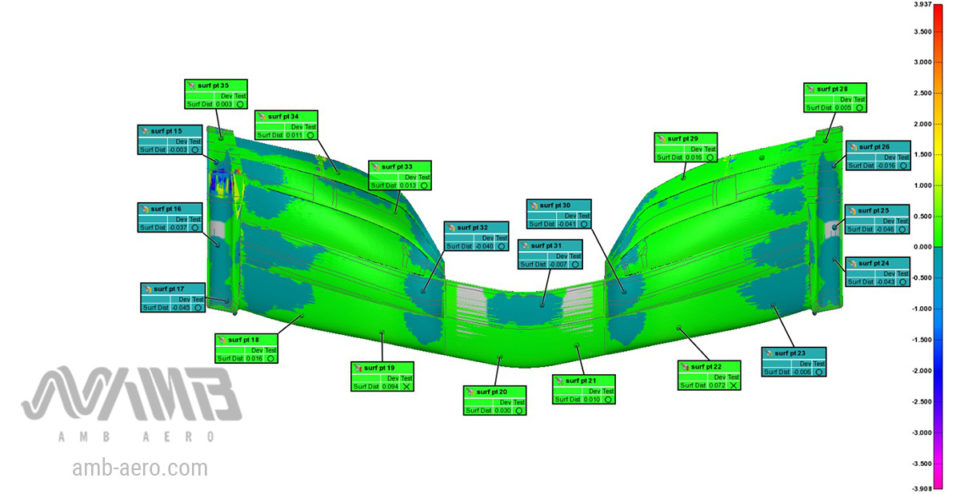

AMB Aero uses the industry-best handheld 3D scanner, Creaform Go!Scan. Offering accuracy to 0.05mm along with gold-standard software tools to transform customer cars into high-accuracy CAD models, which are then used in our in-house wind tunnel model production and CFD aero simulations. Ultra accuracy aerospace-grade scanning is also available using Hexagon tools for micrometer-grade precision. Scanning and reverse engineering are carried out by in-house technicians with experience spanning over 100 vehicles including IndyCar and Formula One.

| Reverse engineering involves capturing the surface details and composition of a physical object to augment, improve or recreate it in 3D. Used across industries like industrial engineering, automotive, aviation and manufacturing, it allows replicating the original object by capturing, analyzing and disassembling its digital 3D replica. |  |

AMB uses top-shelf software tools. Ansys Fluent CFD, Siemens NX for CAD, Geomagic Design X Reverse Engineering, and SolidWorks.

AMB Aero is able to perform aerospace-grade reverse engineering, dealing with extremely small tolerances, as in this example of a Formula 1 front wing:

We can scan your car anywhere in the world

In this 3/4 cutaway you can see the engine room and base body as scanned for Brodie Scott’s Lancer Evolution before our re-development of its aero package. The AMB staff can travel to scan your car anywhere in the world and complete the design work at our offices while you keep racing.

Professional Reverse Engineering & 3D Scanning Workflows

Each project requires the use of different software packages to 3D scan and convert surfaces in a car to useful files that can be fed to CFD analysis programs.

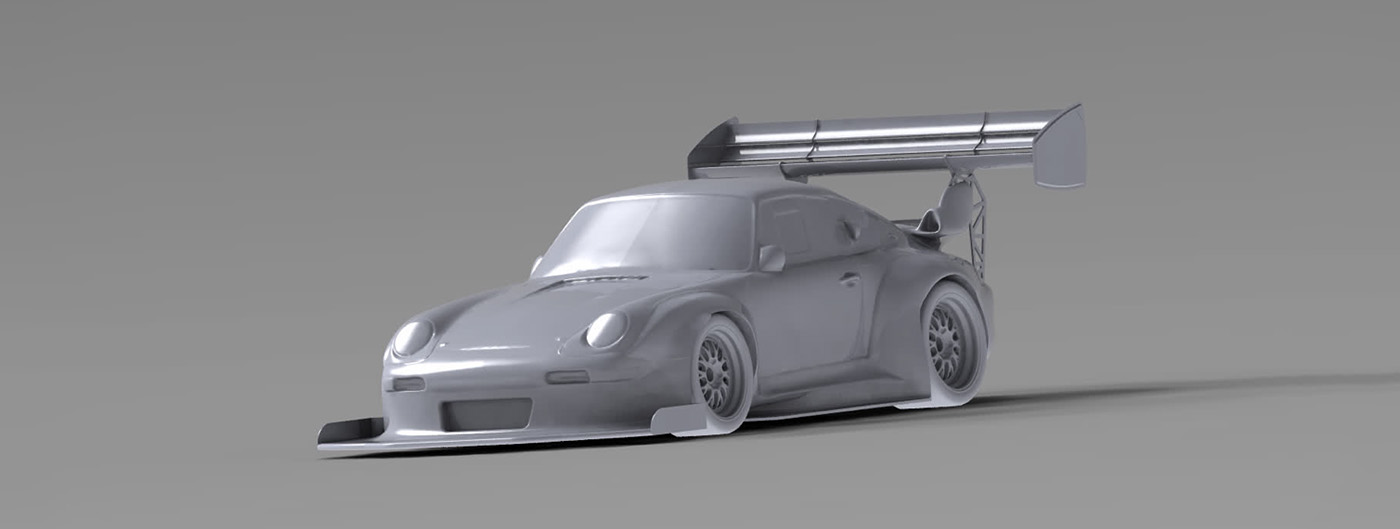

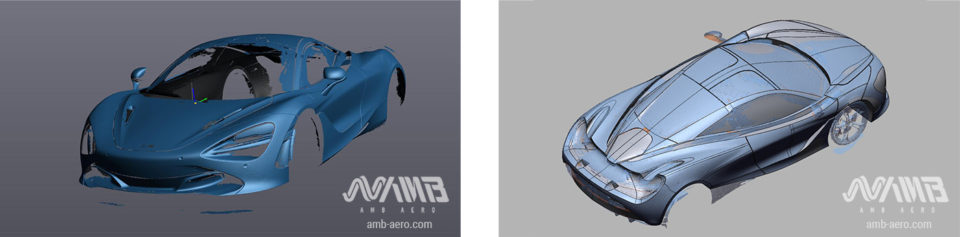

As an example, here is one of our reverse-engineering aerodynamic workflows featuring a McLaren 720S.

Creaform’s Go!SCAN hardware quickly measures any complex surface making it possible to “get it right” the first time (left image). Then, we use Geomagic Design X (right image) to 3D scan data into high-quality, feature-based CAD models. The software combines automatic and guided solid model extraction in a unique way while being incredibly accurate.

At the end of the reverse engineering process, we obtain a highly accurate, automotive-grade CAD model (bottom image).

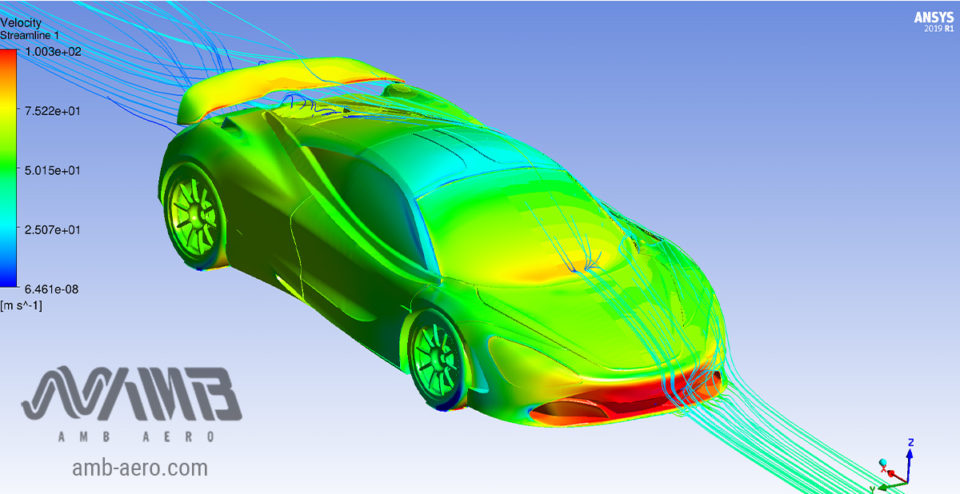

Finally, we import the CAD model into Ansys Fluent CFD software for aerodynamic analysis. The CFD simulation stage requires highly accurate CAD models for optimal results.

We use specialized CAD software like SolidWorks or Siemens NX (below) to further refine or alter CAD models before feeding them to our CFD software.

Want to know more?

We typically 3D scanning and reverse engineering of cars within the context of a larger project, whether it’s CFD-based aerodynamic development or Time Attack, Club Racing or Sportcar / GT Racing aero package development.

We may be able to offer standalone 3D scanning and reverse engineering services depending on your project and needs.